Imagine turning a tough, green plant into something incredibly useful. That’s what decorticating hemp is all about! Hemp, the superhero of plants, can be transformed into a variety of products through this magical process.

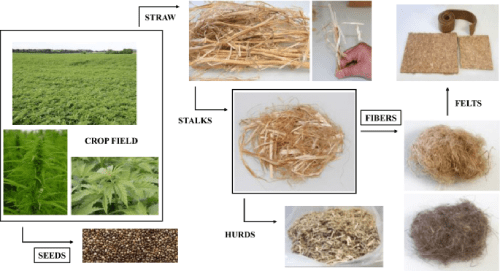

Decortication may sound complicated, but it’s simply a method of breaking down the hemp plant to separate its valuable parts. We’re talking fibers for clothing, hurds for building materials, and even seeds for food. It’s like unlocking the hidden potential of the entire plant!

Ready to dive into the fascinating world of hemp decortication? Whether you’re a curious newbie or a seasoned enthusiast, this post will explore everything you need to know. From how it’s done to why it matters, let’s break it down together.

What is Decorticating Hemp and Why is It Important?

Decortication is the superpower technique that breaks down the tough outer layer of the hemp plant to get to its treasure inside. Essentially, it separates the fibers from the woody core, making each part easier to use for various products.

How Decortication Works

Think of a giant machine that strips the bark off of a tree. That’s pretty close to what decortication does! The process can be done mechanically or manually, but the goal is always the same: to make the plant’s parts more accessible and useful.

The Importance of Decortication

Why go through all this effort? Well, the fibers can be turned into textiles, ropes, and biodegradable plastics. The woody core, known as hurds, can be used in building materials, animal bedding, or even paper.

By decorticating hemp, we’re making the most of this renewable resource. It’s an eco-friendly way to produce sustainable products, reduce waste, and cut down on our reliance on non-renewable materials.

So, next time you see a hemp product, you’ll know that it’s more than just a plant – it’s a versatile marvel made so useful by the magic of decortication!

The Process of Decorticating Hemp: Step-by-Step Guide

Alright, let’s break it down! Decortication can seem complex, but it’s really just a series of straightforward steps. Let’s walk through the process together.

First up, the hemp stalks need to be harvested and dried. This is super important because the dryness allows for easier separation of fibers from the core.

Next, the dried stalks go through a breaker. This machine crushes the stalks and starts breaking them down into smaller, more manageable pieces.

Then, the stalks go through a decorticator. This piece of magic equipment separates the long, fibrous outer layer from the woody inner core. It’s like peeling a banana, but way more technical!

After the initial separation, the fibers and hurds often need to be cleaned. This is usually done using additional machinery or sometimes manually to remove any leftover plant material.

Finally, the separated fibers and hurds are ready to be processed into their end products. The fibers can be spun into textiles, while the hurds can be used for things like building materials or paper.

And that’s it! You’ve got yourself decorticated hemp, ready to take on the world in its new, versatile forms.

Benefits of Decorticating Hemp for Various Industries

Now that we’ve got our decorticated hemp, let’s talk about why it’s a game changer for so many industries!

First off, the textile industry absolutely loves hemp fibers. They’re super strong and durable, making them perfect for everything from clothing to upholstery. Plus, they’re naturally resistant to mold and UV rays.

In the construction world, hemp hurds are used to make Hempcrete. This eco-friendly material is lightweight, insulating, and sustainable, offering a fantastic alternative to traditional building materials.

Paper production is another big winner. Hemp fibers can be pulped to make paper that’s stronger and more environmentally friendly than wood pulp paper because it doesn’t require harsh chemicals or extensive processing.

The automotive industry is also jumping on the hemp bandwagon. Hemp fiber composites are being used to create lighter, stronger, and more sustainable components for cars.

Even the food and wellness industries benefit. Hemp seeds and oils, derived from decorticated stalks, are rich in nutrients and have numerous health benefits.

Common Challenges and Solutions in Decorticating Hemp

Decorticating hemp isn’t all rainbows and butterflies; it comes with its fair share of challenges. But fear not, as there are smart solutions to tackle these issues!

One major challenge is the wear and tear on machinery. Hemp fibers are tough and can be harsh on equipment. Regular maintenance and investing in high-quality, durable machinery can help extend the life of the equipment and reduce downtime.

Another issue is the variability in plant quality. Not all hemp is created equal, and differences in stalk size and fiber toughness can affect the efficiency of decortication. Selecting high-quality hemp varieties and consistent farming practices can ensure a more uniform crop, making the process smoother.

Managing Fiber Consistency

Consistency in fiber output is also crucial. Irregular fibers can affect the quality of end products, especially in textiles and composites. Implementing precision farming and automated sorting systems can help maintain consistency.

There’s also the problem of leftover biomass. After decortication, there is a significant amount of residual material. Instead of viewing it as waste, this biomass can be repurposed for bioenergy or as organic soil amendments, providing an eco-friendly solution to disposal.

Lastly, the initial cost can be significant. Setting up a decortication operation requires a substantial investment. Seeking partnerships, grants, or community programs can ease the financial burden and open new opportunities.

By addressing these challenges with strategic solutions, the process of decorticating hemp can become more efficient, cost-effective, and sustainable.

Conclusion: Maximizing the Potential of Decorticated Hemp

As we wrap up our journey into decorticating hemp, it’s clear that this process holds immense promise. From sustainable textiles to eco-friendly building materials, the potential applications of decorticated hemp are vast and exciting.

However, it’s important to acknowledge the hurdles. From equipment wear and tear to variability in hemp quality, these challenges demand attention. Thankfully, with regular machinery maintenance, high-quality raw materials, and innovative solutions like precision farming, these issues can be managed effectively.

Another thing to keep in mind is that the consistency of fiber output is crucial for high-quality products. Implementing advanced technology and automated sorting can enhance this consistency, ensuring that the resulting hemp products meet industry standards.

And let’s not forget about the leftover biomass. Repurposing what would otherwise be waste into bioenergy or organic soil amendments not only provides an eco-friendly solution but also adds value to the entire process.

Additionally, although the initial costs can be daunting, they shouldn’t be a barrier. Seeking financial partnerships, grants, and community support can significantly reduce the economic impact and make setting up a decortication operation more feasible.

In conclusion, while decorticating hemp comes with its set of challenges, the benefits and potential applications far outweigh the difficulties. By leveraging smart solutions, investing in quality resources, and finding innovative ways to repurpose waste, we can unlock the full potential of this incredible plant. The future of hemp is indeed bright, and with the right approach, it’s ready to revolutionize industries and promote sustainability.